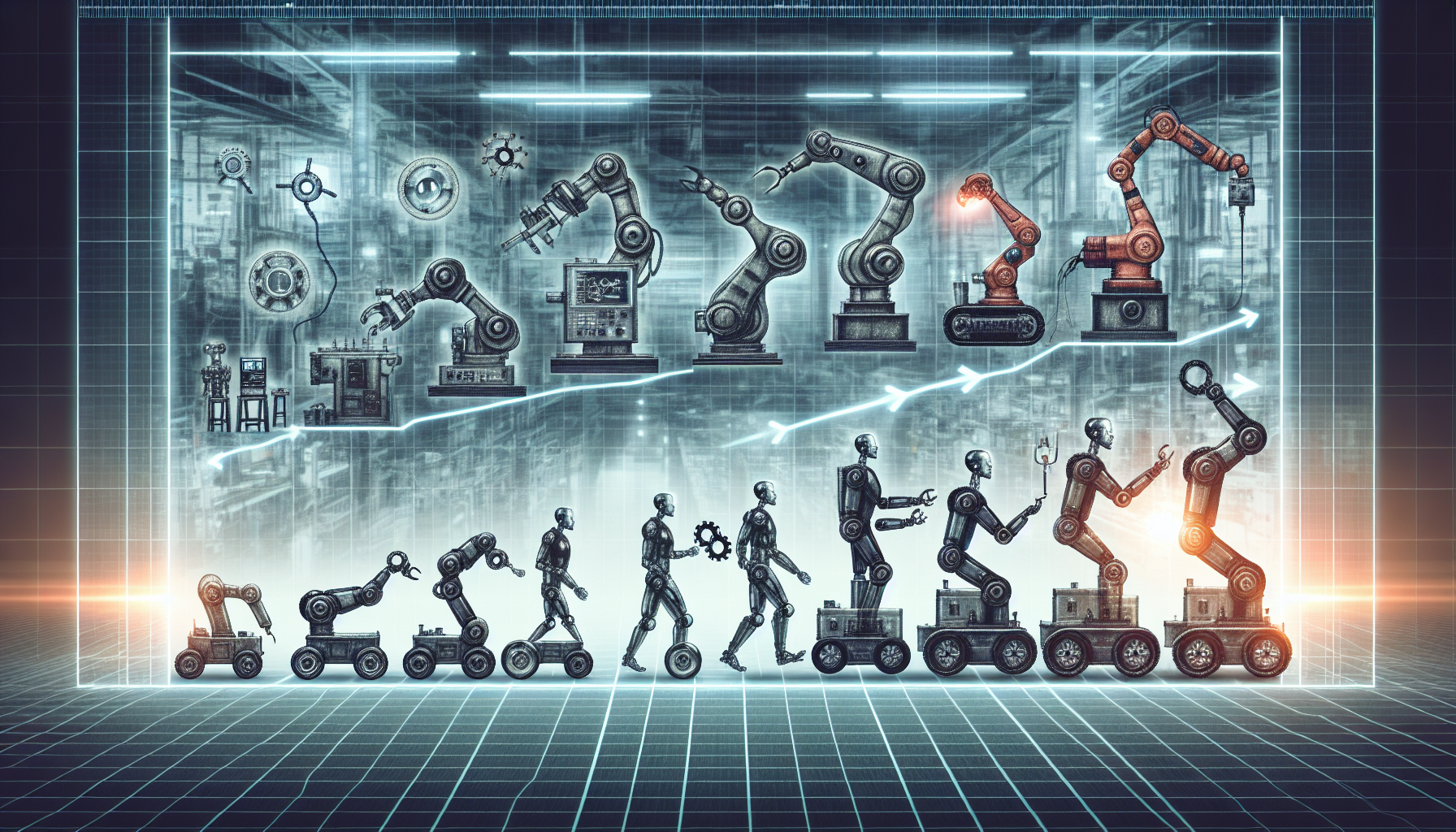

The Evolution of Industrial Robotics

From Simple Automation to Complex Systems

The journey of industrial robotics has been nothing short of astonishing. In the early days, industrial robots primarily focused on simple, repetitive tasks. Think of the early robotic arms that were used primarily in manufacturing environments, performing tasks like welding and painting. Their primary function was limited to speed and precision in specific applications, but as technology advanced, the capabilities of these robots expanded dramatically.

Integration of Artificial Intelligence

One of the most groundbreaking transformations in industrial robotics is the integration of artificial intelligence (AI). AI algorithms allow robots to learn from experience, adapt to changing environments, and make decisions autonomously. For instance, AI-driven robots can now analyze production data in real time, adjust their operations to optimize efficiency, and predict maintenance needs before problems arise. This not only improves productivity but also enhances the overall reliability of manufacturing processes.

Machine Learning and Predictive Analytics

Machine learning is a key component of this AI revolution. Robots equipped with machine learning capabilities can identify patterns in data that humans might overlook. This means they can adjust their movements and operations based on learned experiences. Predictive analytics further empowers these robots by allowing them to anticipate maintenance needs. This means less downtime and more consistent production rates, leading to significant cost savings for companies.

Collaborative Robots: A New Era of Workforce Integration

One of the standout developments in industrial robotics is the rise of collaborative robots, often referred to as cobots. Unlike traditional robots that are typically confined to cages for safety purposes, cobots are designed to work alongside human workers. This collaboration opens up new possibilities for efficiency and productivity.

Safety Features and Human Interaction

Cobots come equipped with advanced safety features such as sensors and cameras, which enable them to recognize and react to human presence. This ensures a safer working environment where humans and robots can perform tasks together without the risk of injury. For example, in assembly lines, a cobot can handle heavy lifting while a human focuses on quality control and intricate assembly tasks.

Impact on Workforce Dynamics

The integration of cobots has also changed the dynamics of the workforce. Human workers are no longer replaced by robots; instead, they are becoming more skilled as they work alongside these advanced machines. This shift encourages a learning culture and develops workers’ capabilities to operate more sophisticated technology. Companies are now focusing on retraining their workforce to embrace these collaborative roles, further enhancing productivity and morale.

Robotics in Supply Chain and Logistics

Another area witnessing remarkable transformation is supply chain and logistics. Robotics is revolutionizing how goods are stored, sorted, and delivered.

Automated Warehousing Solutions

Automated warehouses have become a staple in modern supply chains. Robots, equipped with sophisticated sensors and AI, can navigate warehouse floors to retrieve and store items. These systems help reduce the time it takes to fulfill orders and minimize human errors. For instance, Amazon’s fulfillment centers utilize a fleet of robots that work together seamlessly to ensure that products are picked and packed efficiently.

Last-Mile Delivery Innovations

In addition to warehousing, robotics is changing the landscape of last-mile delivery. Autonomous delivery vehicles and drones are being tested and deployed to deliver packages directly to customers. This innovation not only speeds up the delivery process but also reduces operational costs for companies. Imagine receiving your package within hours of placing an order without the need for human drivers—the future is already here!

The Role of Robotics in Manufacturing

Manufacturing is perhaps where the impact of robotic innovation is most apparent. Traditional manufacturing processes involved a great deal of manual labor. Now, automation is taking over many of these functions.

Additive Manufacturing and Robotics

Additive manufacturing, or 3D printing, in conjunction with robotics, has created new possibilities for production. Robots can manage these 3D printers, allowing for the creation of complex shapes and designs that were previously unfeasible. This technology is not only reducing material waste but also allowing for rapid prototyping and customization in manufacturing processes.

Quality Control through Robotics

Robotic systems are also enhancing quality control measures in manufacturing. With advanced imaging and sensing technologies, robots can conduct inspections far more accurately than the human eye. They can detect minute defects and inconsistencies, ensuring that only the highest quality products reach consumers. This aspect of robotics is crucial for industries where quality is of the utmost importance, such as pharmaceuticals and aerospace.

Sustainability and Eco-Friendly Innovations

As the world grapples with environmental challenges, the role of robotics in promoting sustainability cannot be overlooked.

Energy Efficiency and Waste Reduction

Modern industrial robots are designed with energy efficiency in mind. By optimizing their operations, they use less power, which not only reduces costs for companies but also lessens their carbon footprint. Moreover, through precise manufacturing processes, these robots help minimize waste, making manufacturing more sustainable.

Recycling and Waste Management Robotics

Robotics is playing a critical role in recycling and waste management as well. Automated systems equipped with AI are being deployed in recycling facilities to sort waste more effectively. These robots can identify different types of materials quickly and efficiently, leading to higher recycling rates and less contamination in recycled materials.

Future Innovations on the Horizon

The transformations we’ve seen in industrial robotics are just the beginning. Ongoing research and development promise even more incredible advancements.

Integration with Internet of Things (IoT)

The integration of robotics with IoT technologies is poised to create smarter manufacturing environments. Robots connected to the Internet can communicate not just with each other but also with other machines in the production line. This real-time data sharing can lead to unprecedented levels of efficiency and responsiveness in manufacturing operations.

Advancements in Robotics Mobility and Dexterity

Future developments in robotics will likely focus on enhancing mobility and dexterity. Innovations in soft robotics, for example, aim to create robots that can handle delicate tasks without causing damage. This could open new doors in fields like food processing or healthcare, where precision and care are essential.

In the realm of industrial robotics, transformation is continuous. With each iteration of technology, there’s an opportunity to further redefine possibilities, enhance productivity, and create safer and more efficient workplaces. The world of robotics is undoubtedly one to watch as it evolves at an exhilarating pace.