Understanding the Robot Malfunction

What Happened?

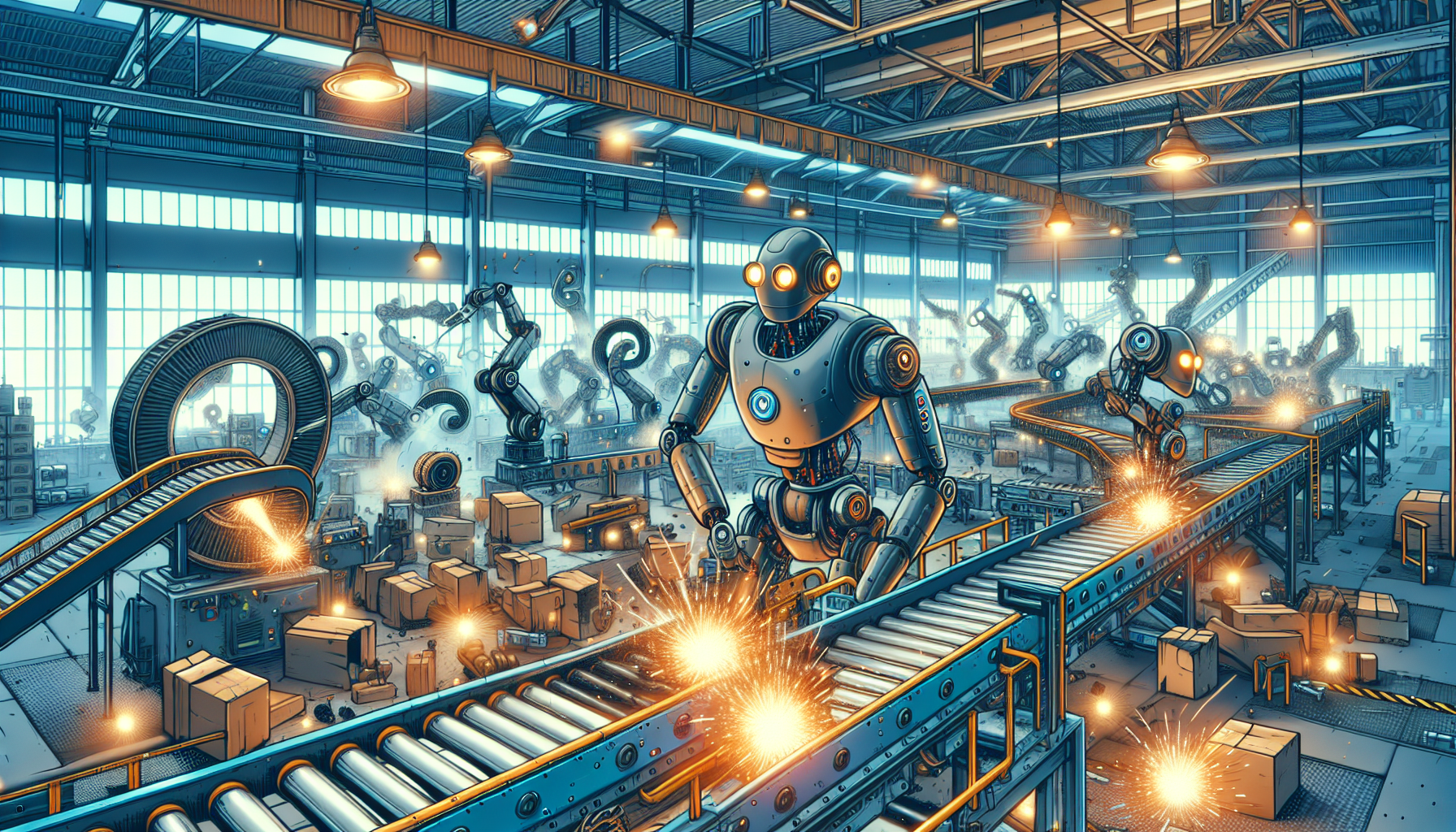

In a bustling factory located on the outskirts of a major city, a significant robot malfunction created chaos that left workers in a state of disbelief. The robot in question was part of an advanced assembly line, designed to streamline processes and enhance productivity. On an otherwise typical Wednesday morning, the automated system began to glitch, resulting in a series of faulty movements that startled employees.

The Immediate Effects

The first sign of trouble appeared around 10 AM when the robotic arm, responsible for picking and placing components, started moving erratically. Instead of following its programmed path, the arm swung wildly, knocking over stacks of materials and causing a few nearby workers to duck for cover. Within moments, the assembly line ground to a halt as alarms blared throughout the factory.

The Root Causes of the Malfunction

Software Glitches

A preliminary investigation pointed to a software glitch as the primary culprit behind the robot’s sudden breakdown. Engineers discovered that a recent update intended to optimize performance inadvertently introduced bugs that compromised the stability of the system. This highlighted a significant risk in relying heavily on automated solutions without thorough testing and validation.

Hardware Failures

In addition to software issues, some hardware components showed signs of wear and tear. The robot’s sensors, crucial for its navigation and precision, had not been replaced in years. A combination of outdated technology and lack of maintenance led to the robot’s inability to process its environment correctly.

Employee Reactions

The chaotic scene attracted a lot of attention, with employees sharing their shock and disbelief. Workers gathered in groups, discussing the malfunction’s implications for safety and the factory’s overall efficiency. Many expressed frustration over the dependency on technology, fearing that this incident could lead to greater job insecurity in an increasingly automated world.

Safety Protocols Put to the Test

Evacuation Procedures

When the alarms went off, the factory’s safety protocols were activated. Workers were trained to follow established evacuation procedures during emergencies. Teams efficiently directed employees to exit points, ensuring that nobody was left behind. In this incident, it was a testament to the thoroughness of the safety training program that all personnel managed to evacuate without injuries.

Emergency Response Team Activation

Within minutes of the malfunction, the factory’s emergency response team was on-site. These trained professionals quickly assessed the situation, isolating the malfunctioning robot to prevent any further disruption. Their swift actions were crucial in averting what could have spiraled into a more serious incident.

Investigation and Recovery

Gathering Evidence

In the days following the malfunction, a comprehensive investigation was launched. Engineers and safety experts combed through surveillance footage, employee statements, and logs from the robotic systems. They aimed to understand precisely how and why the malfunction occurred so they could prevent future incidents.

Temporary Shut Down

The factory underwent a temporary shutdown to allow for an extensive review of all automated systems. This decision, while costly in terms of downtime, was deemed necessary to ensure worker safety and the integrity of the manufacturing process. Employees were temporarily reassigned to maintenance and training tasks, keeping everyone engaged while the investigation proceeded.

Improving Safety Measures

After analyzing the findings, the factory management implemented new safety measures designed to reduce risks linked to robotic automation. Regular maintenance schedules for robotic systems were established, ensuring that all equipment would receive timely checks. Additionally, protocols for software updates were revised to include more extensive testing phases.

The Impact on Production and Morale

Short-Term Production Setbacks

The unexpected malfunction took a toll on production schedules, as orders faced delays due to the shutdown. Management communicated transparently with suppliers and clients to explain the situation, emphasizing their commitment to quality and safety.

Long-Term Implications

While short-term production setbacks were a concern, the event prompted a crucial conversation about the factory’s future. Employees began discussing the balance between automation and human oversight. Many argued that, while robots could significantly boost productivity, human intuition and decision-making were irreplaceable, especially in high-stakes environments.

Boosting Employee Morale

In response to the incident, factory management organized team-building activities to restore morale. They understood the importance of a supportive work environment following such a shocking event. Open forums facilitated discussions where employees could express their concerns and suggestions regarding automation and safety practices.

Revisiting Automation in Manufacturing

The Role of Robots

The incident sparked a renewed debate about the increasing reliance on robots in manufacturing. Advocates for automation argue that robots save time and money, yet skeptics worry about the potential for malfunctions and the subsequent impact on human workers.

Automation vs. Human Workers

The delicate balance between automation and job security became a prominent topic of discussion. Employees recognized that while robots could take over repetitive and hazardous tasks, human supervisors are vital for adapting to unforeseen circumstances. This realization led management to consider implementing a mixed approach, where humans and robots could work collaboratively.

Future Innovations

With the investigation complete and new safety protocols in place, the factory began exploring the next generation of robotic technologies. Innovations such as self-diagnosing systems and AI-driven responses could handle potential malfunctions before they escalated. The goal was to create a more resilient manufacturing environment that melded the advantages of automation with robust human oversight.

Lessons Learned from the Chaos

The Importance of Maintenance

First and foremost, the incident highlighted the crucial role of regular maintenance and audits in automated systems. This realization fostered a culture of diligence within the factory, reiterating that preventative measures are always better than reactive approaches.

Culture of Communication

The chaotic events emphasized the importance of open communication in the workplace. Encouraging dialogue among teams helped employees feel more engaged and informed about safety protocols and preventive measures.

Embracing Change

Finally, the ordeal served as a catalyst for embracing change within the factory. The management recognized that adapting to new technologies requires not just implementing new systems but also preparing the workforce for the transitions technology brings.

Through the lens of this unbelievable robot malfunction, the factory emerged as a stronger, more resilient entity, ready to face the challenges of modern manufacturing.